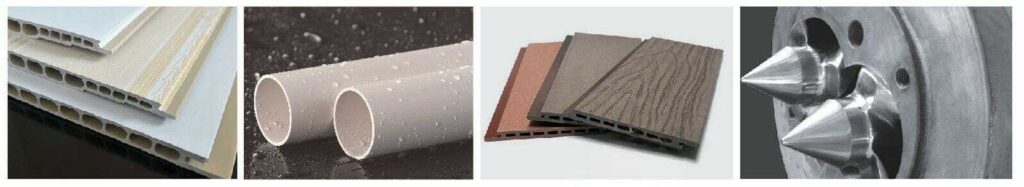

The 92/188 conical twin-screw extruder barrel is one of the core components of a conical twin-screw extruder, primarily used for the compounding and direct molding of thermoplastics such as rigid polyvinyl chloride (UPVC) and wood-plastic composites. It is widely used in the production of pipes, sheets, profiles, plates, and granulation. The “92/188” in its name indicates that the screw’s small end diameter is 92mm and its large end diameter is 188mm, forming a conical structure that facilitates progressive compression and uniform plasticization of the material during extrusion.

Conical twin screw and barrel technical specifications:

| φ35/75 | φ40/84 | φ45/90 | φ45/97 | φ45/100 | φ50/105 | φ51/105 |

| φ55/110 | φ55/120 | φ58/125 | φ61/125 | φ65/120 | φ65/132 | φ68/147 |

| φ70/140 | φ80/143 | φ80/156 | φ80/174 | φ92/188 | φ95/191 | φ105/216 |

Main Technical Parameters and Structural Features:

Materials and Processing Technology: The barrel is typically made of high-quality nitrided steel (such as 38CrMoAlA) and undergoes nitriding treatment to improve surface hardness and wear resistance. The nitriding layer depth is generally between 0.4–0.8mm, and the surface hardness can reach over 930HV, ensuring stability and lifespan during long-term operation.

Structural Form: Conical twin-screw extruders typically employ an integral barrel structure, which helps ensure coaxiality and strength, and reduces the risk of leakage. Some large-scale equipment may also adopt a segmented modular design for easier processing and maintenance.

Temperature Control and Cooling System: The barrel is equipped with a cast aluminum heater or resistance heater, providing high heating efficiency, rapid and uniform temperature rise. It also features a cooling fan or oil cooling system for precise temperature control, preventing material overheating and decomposition.

Integrated Systems: Equipped with a vacuum exhaust system, effectively removing moisture and volatiles from the material, improving product quality.

The screw and barrel work in conjunction with core temperature control to enhance plasticization uniformity.

It can be connected to a variable frequency drive (VFD) motor or a DC motor to achieve stepless speed regulation, adapting to different formulations and process requirements.

Application Compatibility This specification of cylinder is commonly used in SJSZ92/188 model extruders, suitable for direct molding of PVC powder, and also supports modified plastics and recycled material processing, with a typical output range of 200–800 kg/h.

Product Category:

| Sheet extruder screw cylinder | Blow film extruder screw barrel | Blow molding extruder screw barrel | Recycling granulation extruder screw cylinder |

| Wire and cable extruder screw | Plastic steel strip extruder screw barrel | Wire drawing extruder screw barrel | Film coated extruder screw barrel |

| Cast film extruder screw tube | Plate extruder screw barrel | Spinning extruder screw barrel | Conical twin-screw tube |

| Parallel twin-screw barrel | Injection molding machine screw cylinder | Food extruder screw tube | Chemical extruder screw barrel |

| Non standard screw cylinder | Customized extruder | ||

If some screw products do not have a list, please feel free to contact us by email and we will reply within 24 hours!

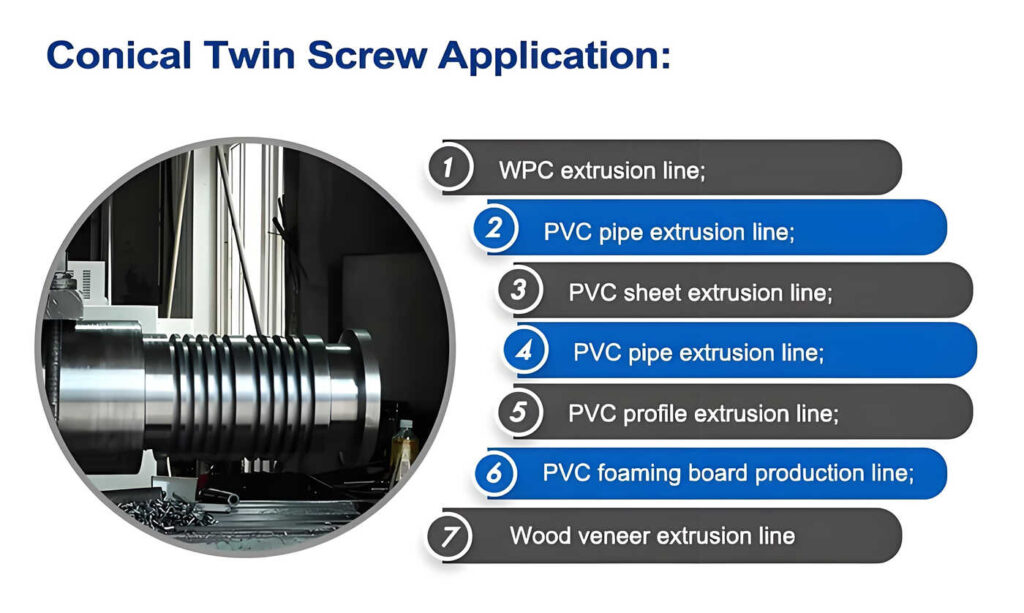

We can quickly reach any country and region through sea freight, air freight, international express delivery, and other transportation methods. We have stock of standard sized screws and barrels, and once confirmed by the customer, they can be delivered within 5-7 days.

We have many experienced engineers who can quickly customize various types and types of screw barrel according to customer requirements. Before produce, technical will check every detail with salesman according with clients’ request. Under produce, every step will be inspected before next process. And every salesman will follow some time to make sure 100% correct and reduce communication error and work undelay. We put quality at a high level and the price is middle level.

Our sales team is familiar with the production and export processes and has nearly 10 years of customer service experience. Every salesperson can ensure that the customer’s requirements and our screw barrel are 100% accurate in production details. We will solve any cargo issues until the customer is satisfied.